Pumps are the unsung heroes of countless industries, from oil and gas to wastewater management and food production. Among the various types of pumps available today, the PC pump (progressive cavity pump) stands out for its versatility and efficiency. In tandem with a focus on quality pumps, industries can ensure reliable operations, reduced downtime, and improved output.

This article explores the role of PC pumps, the significance of quality in pump selection, and how these tools drive efficiency and innovation in modern applications.

What is a PC Pump?

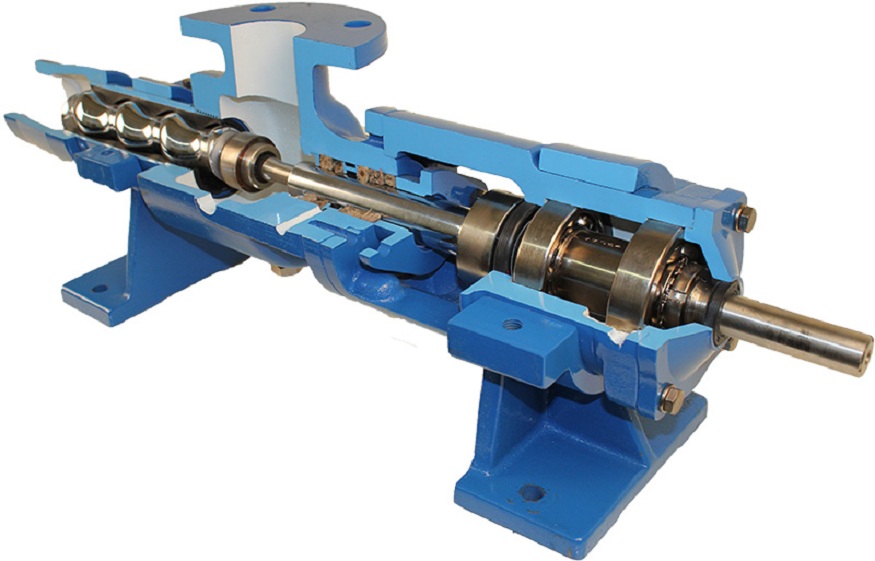

A PC pump, or progressive cavity pump, is a type of positive displacement pump that excels in handling viscous fluids, slurries, and sensitive materials. It operates using a rotor that turns within a stator, creating cavities that move fluids steadily from the inlet to the outlet.

Key Features of PC Pumps

- Consistency: PC pumps deliver a steady, non-pulsating flow, making them ideal for applications requiring precision.

- Versatility: These pumps handle everything from low-viscosity liquids like water to high-viscosity fluids such as oils, sludges, and even solids-laden liquids.

- Gentle Handling: Their design minimizes shear, preserving the integrity of sensitive materials like emulsions or food products.

Applications of PC Pumps

PC pumps are used across a wide range of industries due to their adaptability.

1. Oil and Gas Industry

In upstream and downstream operations, PC pumps excel at transporting crude oil, especially when mixed with sand or water. Their ability to handle abrasive materials and viscous fluids ensures optimal performance in challenging environments.

2. Wastewater Management

PC pumps are crucial in sewage treatment plants, where they move sludge and slurry with high efficiency. Their durability makes them a cost-effective choice for handling waste.

3. Food and Beverage Sector

In industries like dairy, bakery, and brewing, PC pumps play a vital role in transferring delicate products such as yogurt, dough, and beer without compromising quality.

4. Chemical Processing

Chemical plants rely on PC pumps for their ability to handle corrosive and hazardous materials safely, ensuring the protection of both workers and equipment.

The Importance of Quality Pumps

While the type of pump is critical, the quality of the pump is equally essential. Investing in quality pumps ensures long-term reliability, reduced maintenance costs, and enhanced operational efficiency.

Characteristics of Quality Pumps

- Durability: Made from robust materials that withstand wear and tear.

- Efficiency: Designed to minimize energy consumption while maximizing output.

- Adaptability: Capable of handling a range of materials and operating conditions.

- Ease of Maintenance: Simple designs that facilitate quick and cost-effective repairs.

How PC Pumps Exemplify Quality Pumps

PC pumps are a benchmark for quality in the pump industry due to their superior design and performance.

Efficiency in Challenging Conditions

Unlike some pump types that falter under extreme conditions, PC pumps maintain consistent performance in high-pressure and high-viscosity scenarios.

Longevity

The robust construction of PC pumps ensures they can endure abrasive materials and corrosive environments without frequent breakdowns.

Cost-Effectiveness

Though the initial investment in PC pumps may be higher than in some alternatives, their efficiency and durability result in lower total ownership costs over time.

Choosing the Right PC Pump for Your Needs

Selecting the right PC pump requires an understanding of the specific demands of your application. Here are some factors to consider:

1. Fluid Type

Understand the viscosity, abrasiveness, and sensitivity of the fluid you’ll be handling. PC pumps are particularly well-suited for materials that are thick, abrasive, or prone to shearing.

2. Flow Rate Requirements

Ensure the pump can meet the volume and pressure demands of your operation without overloading.

3. Material Compatibility

Check that the materials used in the pump construction can withstand the chemical composition of your fluid to avoid corrosion or degradation.

4. Maintenance and Support

Opt for pumps from manufacturers that offer strong customer support, easy access to spare parts, and straightforward maintenance procedures.

Why Quality Pumps Matter in Every Industry

Quality pumps are not a luxury; they are a necessity for industries that depend on continuous, reliable performance. Here’s why quality matters:

Reduced Downtime

High-quality pumps are less prone to failures, ensuring uninterrupted operations.

Energy Efficiency

Advanced designs and superior materials reduce energy consumption, leading to lower operational costs.

Environmental Impact

Well-designed pumps minimize leaks and wastage, contributing to sustainability.

Innovations in PC Pump Technology

The pump industry is constantly evolving, and PC pumps are at the forefront of innovation.

Smart Technology Integration

Modern PC pumps often include sensors and IoT capabilities, allowing for real-time monitoring and predictive maintenance.

Eco-Friendly Designs

Manufacturers are increasingly focusing on energy-efficient and sustainable pump designs, reducing the carbon footprint of industrial operations.

Customizable Solutions

From tailored stator materials to modular designs, PC pumps now offer a higher degree of customization to meet specific application needs.

The growing demand for PC pumps and quality pumps highlights their vital role in various industries. Whether it’s the consistent performance of PC pumps in transporting viscous fluids or the reliability of quality pumps in critical operations, these tools are indispensable for modern industrial processes.

By prioritizing efficiency, durability, and adaptability, businesses can leverage these pumps to achieve greater productivity and cost savings. As technology continues to advance, the capabilities of PC pumps will expand, further solidifying their position as a cornerstone of industrial innovation.

Investing in the right pump isn’t just about meeting today’s needs; it’s about preparing for the challenges of tomorrow. Whether you’re in oil and gas, food production, or wastewater management, choosing a PC pump ensures you have a solution that delivers performance, reliability, and value.